One of the main advantages of the mobile system is the ability to process work orders efficiently and at site. This article with cover work order processing in 3 parts: Materials, Labor and Completion.

Materials

Charging materials to a work order can be done directly on or from the Inventory Issues screen. This article will look at adding the materials to the work order directly.

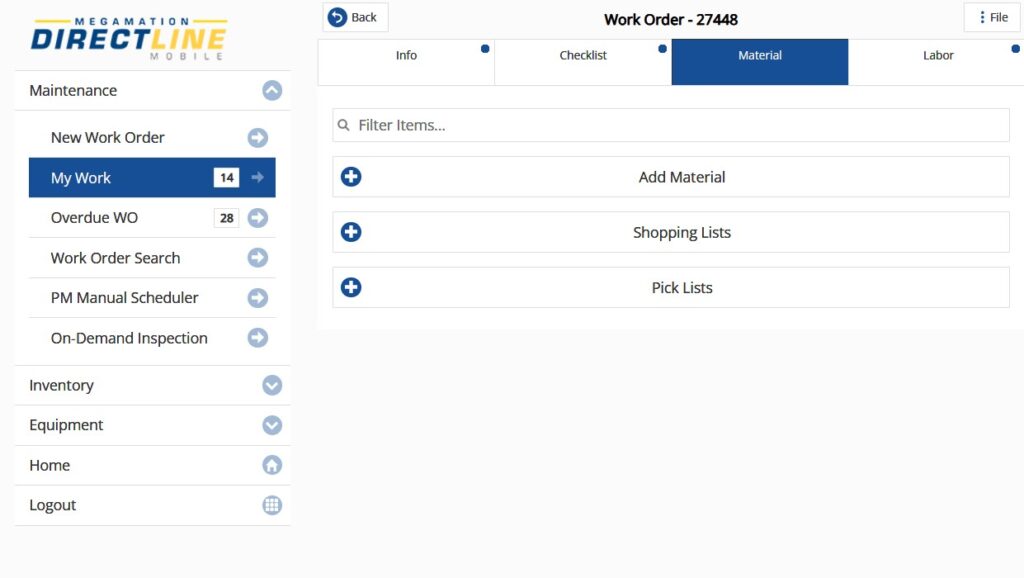

On the work order go to the Material Tab.

Hit Add Material to begin adding parts.

Note: For more information on Shopping Lists and Pick Lists contact Megamation Support.

Material Types

There are 2 types of materials that can be added to a work order from this screen, Inventory Parts and Non Inventory Parts.

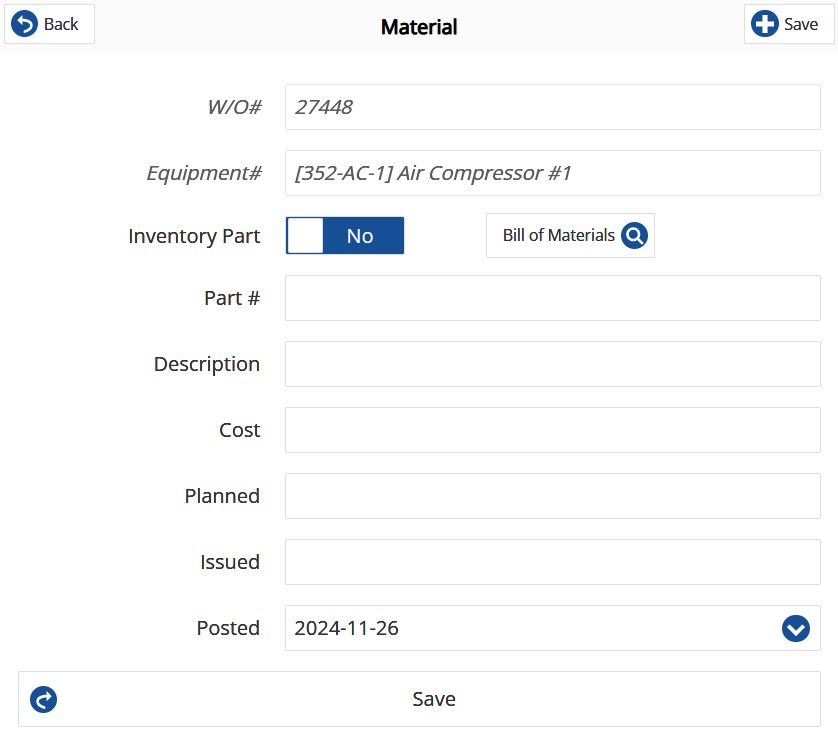

- Non Inventory Part

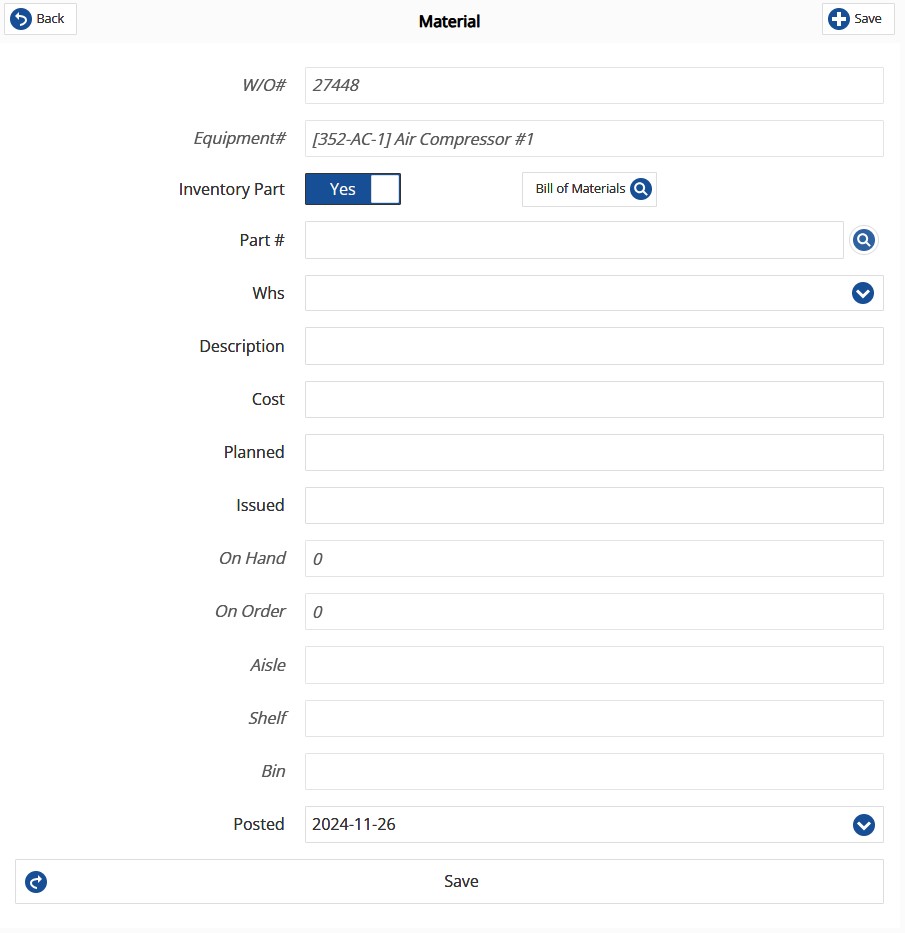

- Inventory Part

Follow this process for adding any parts that are not in the inventory list.

Leave the Inventory Part slider on No.

Part # – Here enter a reference for the item. Example: BOLT, PLIERS, or, SERVICE

Description – Describe what the materials are

Cost – Enter the material cost per unit.

Planned – The quantity of parts intended to be used on the work order has not yet been used. Entering a quantity here does not charge any cost to the work order.

Issued – The qauntity of parts that have been used on the work order.

Posted – The date the parts were used on the work order.

Set the Inventory Part slider to Yes

Set the Inventory Part slider to Yes

Part # – Enter a valid part ID or tap the Magnifying glass button to use the

Description – Will be filled from the part description on the Inventory Detail Entry

Cost – Will fill out the average cost from the inventory entry. This can be edited if needed.

Planned – The quantity of parts intended to be used on the work order has not yet been used. Entering a quantity here does not charge any cost to the work order or update on hand quantity.

Issued – The quantity of parts that have been used on the work order. This field will update the on hand quantity one the work order is saved.

Posted – The date the parts were used on the work order.

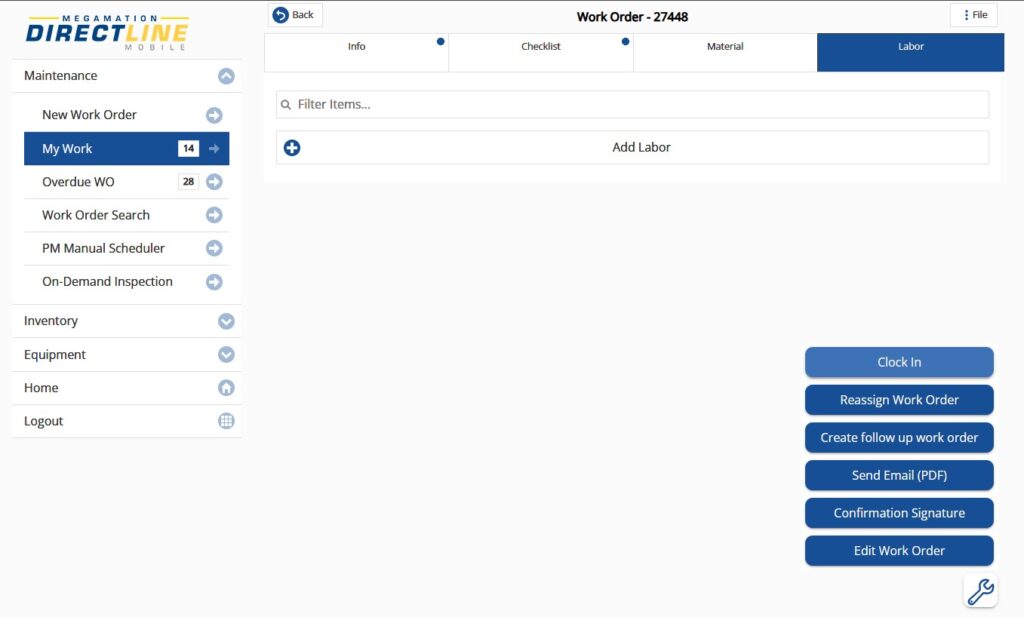

Labor

Adding labor to a work order from Directline Mobile provides the opportunity

There are 2 ways to add labor to a work order in Directline Mobile and both will be described below.

- Clock-In/Clock-Out

- Add Labor

Using the clocking function gives the most accurate picture of time spent on a work order as well as giving visibility to planners and managers of what employees are working on.

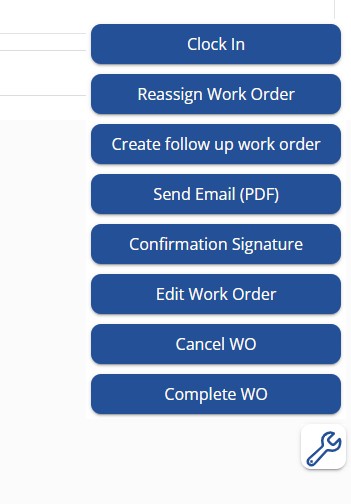

To clock in, hit the wrench icon at the bottom of the work order screen and tap clock in.

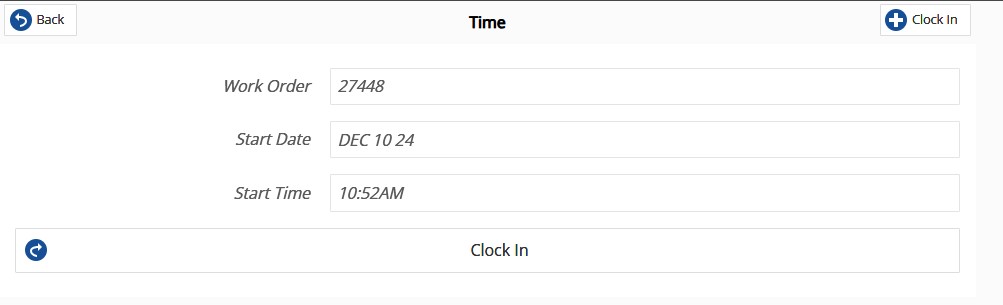

The start date and time will be displayed for confirmation. Hit Clock in.

—

Note: A user can only be clocked into one work order at a time. If they need to leave a job to do something else, they can clock out into a different work order without closing the first.

—

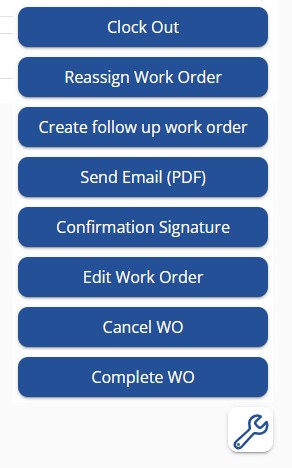

To Clock out of a work order, hit the same wrench icon and hit Clock Out (clock out only appears on work orders when you are clocked in).

Work time will be calculated, but the stop time can be changed if needed. Add comments.

If the job is complete, flip the Ready to Close slider to yes. This will change the status of the work order to RC and remove the WO from the My Work List for the user.

The Add labour function can be used to add time and complete the work order without clocking in or out. This option can be used to add time to a WO that is not issued to you.

Add time by clicking the Work TIme drop down and selecting an amount of time from the display.

Add comments in the comments field.

If the job is complete, tap the Ready to Close slider to switch it to yes.

Hit Save.

Once the ready to close slider has been switched to yes, the WO status will change, and the work order will drop off the user’s My Work list.