The work order processing is designed to allow processing the WO from creation to completion.

This screen has two modes, Planning and Completion. Planning mode allows you to create the work order and enter planning information such as Issue to, estimate hours, planned materials etc. Completion mode allows you to add completion infor mation such as Completed by and Completed Date as well as actual hours and issued materials.

This article will explain how to switch between modes, as well as describe the differences and how to use both.

Navigation

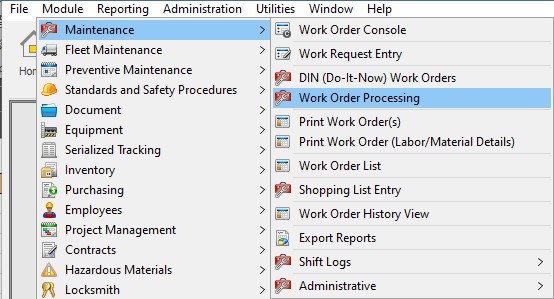

Access the Work Order Processing screen by going to :

- Module

- Maintenance

- Work Order Processing

Selecting Modes

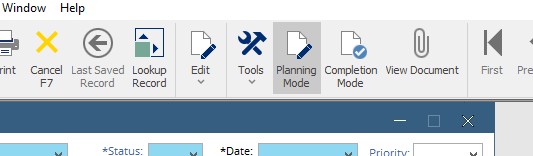

There are 2 modes for this screen, and they can be switched using the buttons in the Toolbar at the top of the screen.

Planning Mode – Use this mode to create a new work order, add planning information and planned labor and material information.

Completion Mode – Use this mode to enter completion information to close the work order and add actual hours and materials used.

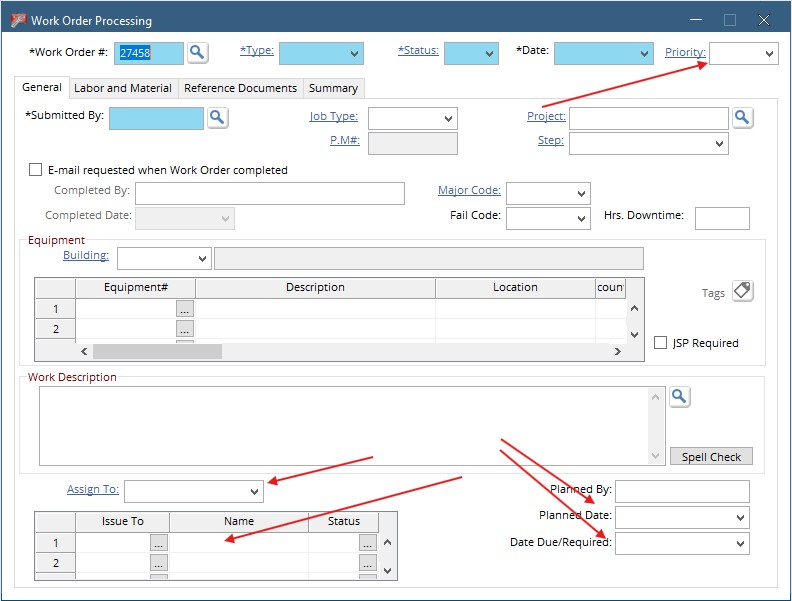

Planning Mode

- General

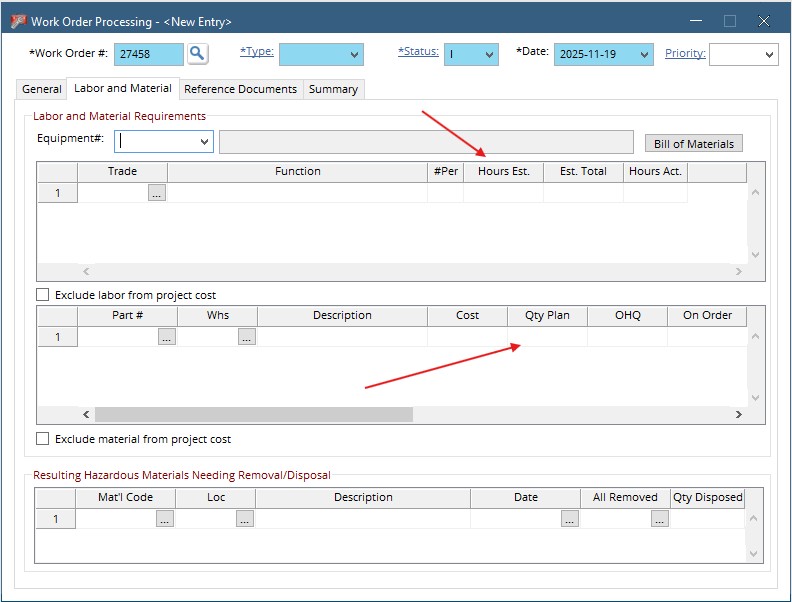

- Labour and Material

– Use the Assign to and Issue To fields to determine who will do the work and when.

– Set the Priority and Due Date for the workorder.

– Add Planned By and Planned date

– Add estimated hours to use for labour planning.

– Add Planned material. No parts are removed from Inventory but quantity can be planned and ordered if necessary.

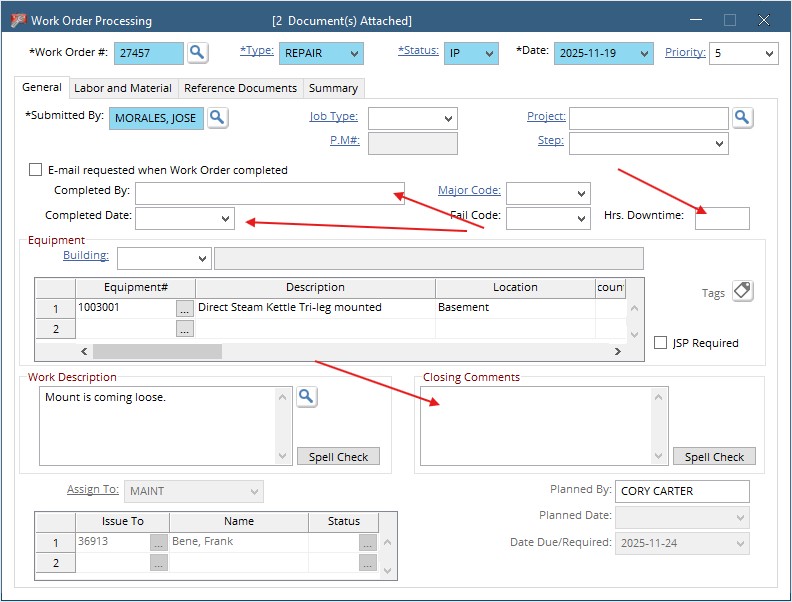

Completion Mode

- General

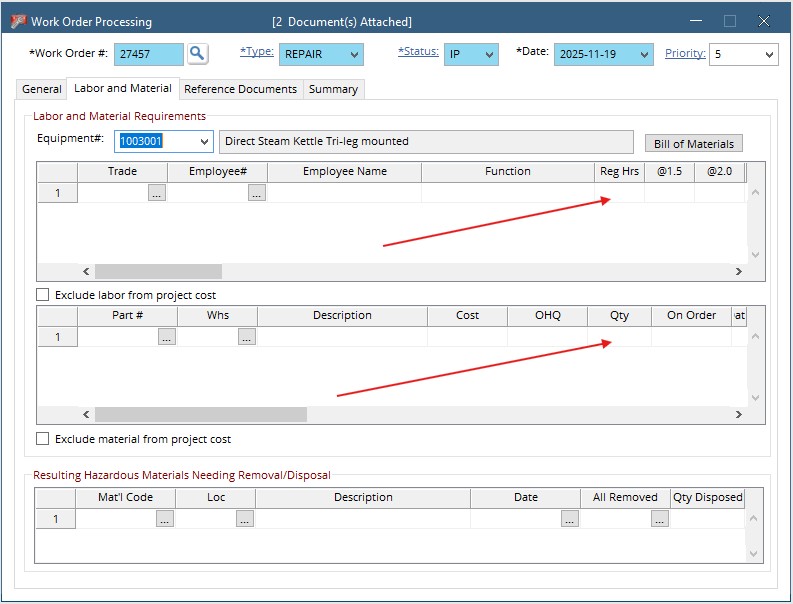

- Labour and Material

– Fill in Completed by and Completed date to close the work order. Once these fields have been filled, saving the WO will change the status to ‘closed’, and the work order can no longer be modified.

– Enter Downtime Hours once work has been completed.

– Add closing Comments. This should describe the actions taken to resolve the issue.

– Add Actual hours spent working on the job as either REG or overtime hours. Labor costs for the work order will be calculated from these hours.

– Add issued quantity for any parts used. this will remove the parts from inventory when the WO is saved and add them to the material cost of the WO.